Carbon fibre reinforced polymer properties

Ask any specialist tradesperson about their adoration for carbon fibre reinforced polymer composites, or CFRPs, and they will give you a long list of pros. CFRP composites are strong and stiffer per unit, lightweight (1/5th the weight of steel with comparable strength), and extremely resistant. What’s not to love?

But for those who don’t know – what are carbon fibre reinforced polymer composites, and why are they so pivotal to today’s structural strengthening jobs?

What is carbon fibre reinforced polymer composites (CFRPs) used for?

Due to the increased strength and high anti-corrosive properties, carbon fibre reinforced polymer (CFRP) are used to reinforce all kinds of structural elements in varying conditions. This includes buildings, bridges, sewage works, and more.

What are carbon fibre reinforced polymer composites made of?

Although the term `CFRP` is inclusive of polymer, this matrix of composites can also be made from plastic or thermos-plastic. Here is the process that is used to make our CFRP composites, which is the polymer-based one:

- The primary element of CRFPs is always a carbon filament, which is produced using a precursor polymer such as polyacrylonitrile (PAN, a white powder), rayon, or petroleum pitch.

- These materials are treated to a spinning process, where the polymer fibres are made – 1,000-60,000 of them depending on the amount of CFRPs!

- Next, the polymer fibres are heated up to rid them of any non-carbon atoms, which are not needed within CFRP composites. This will leave the carbon fibre aspect. The heating process involves oxidising at 200-300 degrees then carbonising at 1200-1800. Clever stuff isn’t it?!

- CFRPs are commonly compared to GFRPs, which are made of reinforced glass. GFRPs are generally cheaper, though CRFPs are far superior when it comes to their key properties – strength, light-weight, resistance.

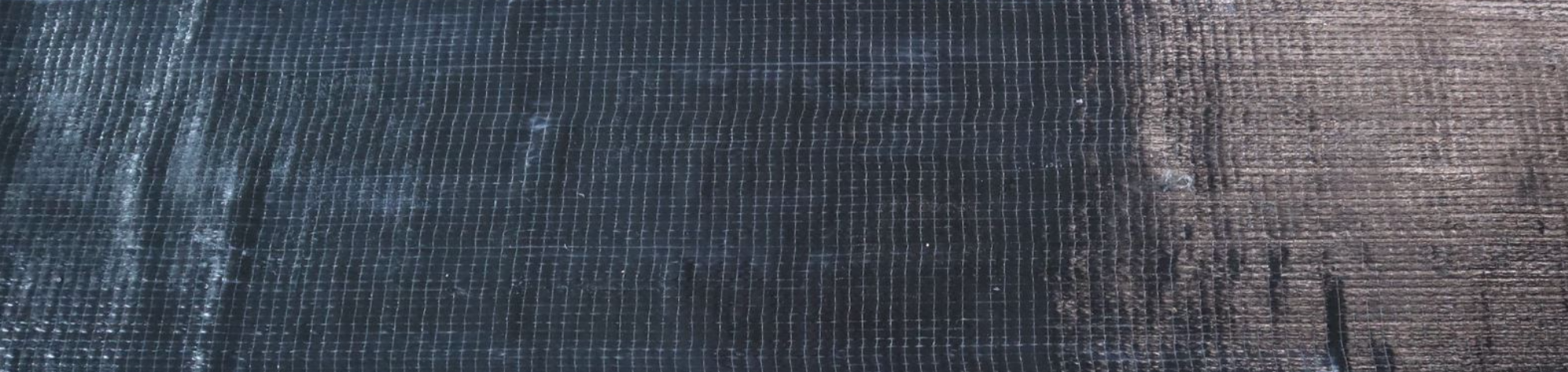

CFRPs in action: Our Laser House project

We recently treated a former printing press and gin distillery to CFRPs: Laser House near the Barbican in central London. This prestigious development required partial demolition of the existing structure and construction of extensions to the existing building. We were charged with providing the correct structural strengthening methods (CFRPs) to make this multi-million-pound makeover work!

Please see our image gallery below:

Ask us about CFRPs

At CCUK, we are experienced applicators of CFRP composites, and we’ve seen what they can do first-hand! If you’d like to book your free feasibility survey & cost analysis, simply follow this link and pick a time that suits you.