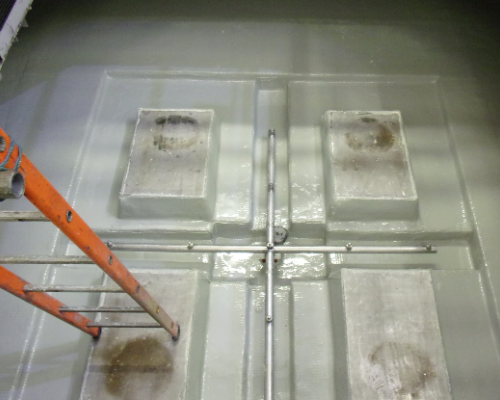

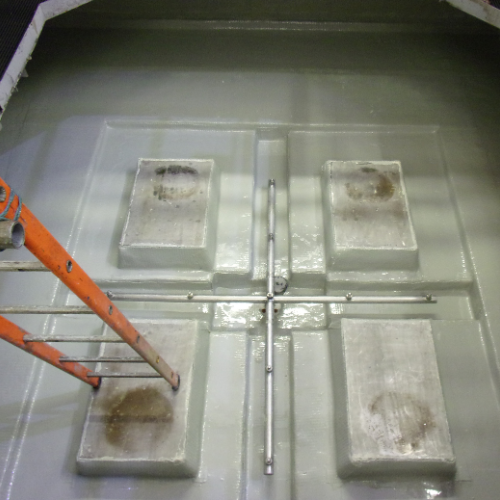

Scope of Work: CCUK was appointed to deliver a highly specialised composite lining solution at EDF’s Hinkley Point facility—one of the UK’s most tightly regulated and operationally complex nuclear sites. The project involved the application of a high chemical resistance Glass Fibre Reinforced Plastic (GFRP) system to the flask wash area, a critical zone subjected to aggressive wash-down operations. The primary objective was to provide a durable, chemical-proof lining that would protect structural elements and extend the operational lifespan of the area, ensuring safe and efficient handling of nuclear flasks well into the future.

HIGH CHEMICAL RESISTANCE GFRP LINING AT EDF HINKLEY POINT - NUCLEAR FLASK WASH WATERPROOFING AND PROTECTION

Duration:

3 weeks

Project Details

The Challenge

The project presented multiple technical and operational challenges. All CCUK personnel were required to undergo comprehensive security vetting and obtain full nuclear site clearance—an intensive process that validated not only their credentials but also their discipline and readiness for work in highly controlled environments.

Once on site, the team operated in confined spaces with elevated temperatures and under strict radiation safety protocols. Works had to be executed without disrupting any of the site’s ongoing activities, necessitating precise coordination with EDF’s operations team. The procedural and environmental controls in place demanded rigorous adherence to safety, timing, and quality standards at every stage.

The Solution

Drawing on extensive experience in regulated environments, CCUK deployed its accredited GFRP composite system—specifically designed for high chemical resistance and long-term durability. Installation was carried out by trained and cleared specialists, using refined application methods to ensure seamless coverage within the challenging site constraints. A phased approach to scheduling allowed works to be completed alongside live site operations, without causing disruption to the facility’s core functions.

All activities were delivered under strict quality assurance protocols, including continuous radiation monitoring, procedural compliance, and detailed client communication throughout the process.

The Result

Despite the high-risk, highly regulated setting, the project was completed on time, to specification, and with zero incidents of contamination or non-compliance. The newly installed CCUK GFRP lining provides a robust, long-term chemical barrier, safeguarding the structural integrity of the nuclear flask wash area against corrosive wash-down processes.

This successful delivery reinforces CCUK’s proven ability to execute technically demanding works in nuclear and safety-critical environments, and highlights our ongoing commitment to performance, quality, and long-term client partnerships.